Box Girder Crane: Gantry Crane &Overhead Crane Box Girder Design

Box girder cranes have a very light weight to span length ratio. In many cases box girders reduce the size of the runway and building structure required to support the lifted load, thus reducing the overall building cost.One of the most cost-effective ways for lowering the cost of your steel building project is to use overhead cranes made of box girders rather than structural beams. Both low- and high-capacity cranes are available.

Single beam overhead box girder crane

Single girder box girder crane

- Top running box girder - Box-type main crane girder which spans up to 30m (98 ft) and can uplift load up to 1ton -5 ton, 10 ton, 20 ton, 35 tonnes

- Under running -Under running single girder cranes which span up to 22m (72 ft) and weight lift load up to 10 tonnes.

Box girder

Chinese style box girder

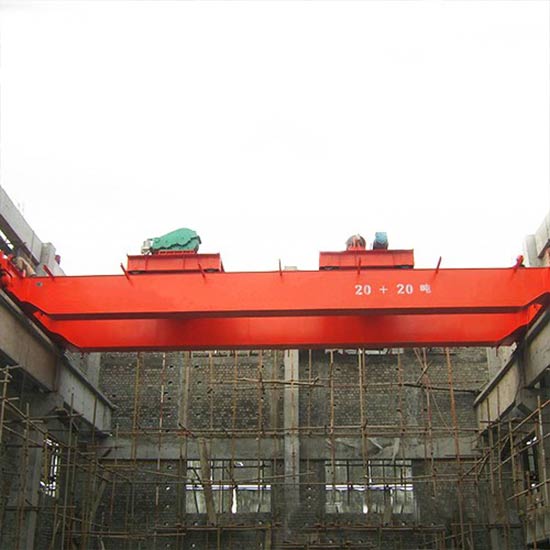

Double beam overhead box girder overhead crane

Double beam box girder crane

The most common form of girder structureutilized by box girder overhead cranes is the box-type girder structrue. The upper and lower cover plates, as well as two vertical cover plates, make up the box crane girder, which is made up of closed box-shaped section constructions. The lower border of the web and the lower cover should be formed of parabolic shape to minimize weight and provide an equivalent strength beam. However, to make manufacture easier, the web is normally rectangular in the middle and trapezoid on both sides, allowing the lower cover to be tilted at both ends.

Usually, the top running double girder box girder overhead crane is usually adopts box shaped girder design for heavy duty material handling with capacity from 5 ton to 320 ton.

Fabrications of box girder overhead crane

Crane girder mainly use box-type structure and truss structure, while the box-type structure crane girder is the most widely used.

The entire steel plate welding can be used on the box-type crane girder, making active and semi-active welding simple. It has the advantages of easy planning, good fabrication technology, and batch production suitability. It is the most extensively utilized method of construction.

Box girder & box beam design

Box girder & box beam design

Box girder & box beam design

Box girder & box beam design

Box girder & box beam design

Box girder & box beam design

Box girder gantry crane

Gantry crane box girder is mainly made of steel plate welded into box structure, which has the advantages of high safety and reliability, stiffness and other advantages, but the box girder structure of the gantry crane has the features of high cost, heavy dead weight, and relatively poor wind resistance.

Fabrications of gantry crane with box girder design

In the following, these are the production pictures of a box girder gantry crane for your reference. If you need more information, please feel free to contact us by leave a message below or contact us by WhatsApp: +86 151 3871 1597

Box structure of ground beam for gantry crane

Rib plate to threnghen the box girder

Steel support to prevent deformation of box structure

Inner sider of huge box girder of gantry crane

Advantages of box girder cranes in steel-building construction

Someoverhead cranemanufacturers, such as EOTCRANEKIT, custom build their cranes from box girders rather than wide flange beams. The advantages of this technique are many.

- Lower cost of steel:Building with box girders requires less steel. One of the main costs of anoverhead craneis the materials used in its manufacture and the less steel that is needed, the lower the cost of steel in the crane.

- Lower weight:Overhead cranesbuilt from box girders are also lighter than comparable cranes built from structural steel. Columns can be lighter weight, runway beams can be lighter, and the building structure can be a lighter weight overall.Also, the lower weight of the box reduces the structural requirements of the runway design by lowering the crane loads on the runways and support columns.

- Better hook height:Another advantage of box girder cranes, whether single girder or double girder, is that they enable you design the girder depth to improve hook height.

- Greater loading capability:A further advantage of box girder cranes is that they possess greater loading capabilities and are able to span longer bridge distances than their structural-steel counterparts.

- Greater design flexibility:Steel buildings need to be designed to loading requirements. When you determine the load of your crane, you also consider the dead load (on the building all of the time) and the live load (on the building when the crane is lifting or moving a load). The advantage ofoverhead cranesbuilt from box girders is that they give you more design flexibility, since they are lighter than comparable cranes built from wide flange beams.

Conclusion

You're probably aware that a variety of factors influence material costs if you're planning to design or build a steel structure.

One of these variables is the engineering requirements for your building to meet local wind, snow, and seismic code standards, as well as loading requirements. Have you considered that the type of overhead crane you install in your steel structure affects the price?

Consider constructing an overhead crane with box girders. You will save money, have greater design flexibility, and have greater loading capacity.